Companies in diverse sectors, including consumer electronics, automobiles and automotive parts, pharmaceuticals, and apparel are warning they are mere weeks away from running out of production-critical supplies as Chinese factories shut down and cross-border commerce is contained to limit contagion.

There are few precedents for projecting the knock-on effects of the latest coronavirus to emerge in China on that country’s economy, its trading partners and, ultimately, global growth.

The 2003 outbreak of the SARS coronavirus was credited with trimming 2% off China’s growth in second-quarter 2003 and 1% off China’s GDP growth for the year, according to the Financial Times. Much of the loss was sustained by the travel and tourism industry, and contained within China’s economy, which rebounded in the third quarter.

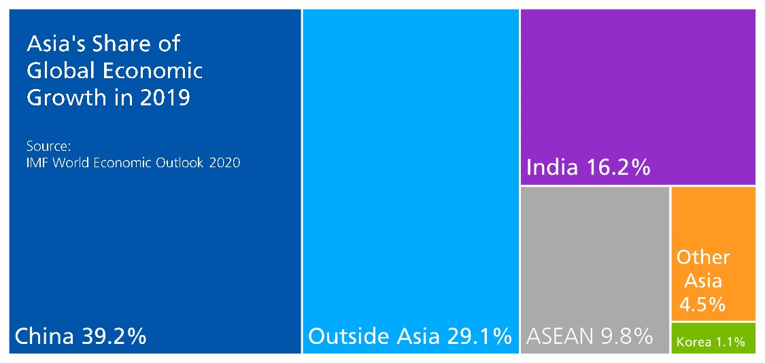

That was then. In contrast with 2003, when China accounted for 4.3% of global production, the IMF has estimated China’s share of the world’s output in 2020 at almost 17%. China makes an even bigger contribution to global economic growth, accounting for fully 39.2% of last year’s gain:

The U.S. trade wars have provided ample evidence of the extent to which supply chains and assembly lines have not merely globalized but almost invariably been routed through China at some point in the production-to-market cycle. [See, for example, our blog’s coverage of the Trade War Flattens U.S. Import Peak Shipping, U.S. Auto Exports and the Impact of Shifting Trade Policy, or The Broad-Gauge Impact of Section 232 Tariffs on Steel and Aluminum.]

As the Economist points out, most electronic devices sold in the U.S. are assembled in China. China, in turn, relies on imports for most of what’s needed to make its electronics products – an estimated 55% of inputs used in its robotics, 65% of inputs for cloud computing, and 90% of the inputs used in semiconductors. When China closes shop, the cross-border assembly line grinds to a halt, wholesalers and retailers run short of inventory, sales are lost and revenues take a hit. In early February, publicly-held companies making smartphones, phone components and modems were already issuing warnings that first-quarter 2020 earnings goals would likely be missed.

Coronavirus Stress Test: Evaluating Supply Chain Exposure

Descartes Datamyne trade data can help evaluate supply chain exposure to this latest market disrupter and point to alternate sources.

Start with the macro view of China’s exports:

Not surprisingly, China’s coastal provinces and municipalities dominate exports. Our trade data provides a closer look at the mix of outbound products and their destinations. We’ll focus here on Hubei Province, where the first factory closures, transport restrictions and quarantines aimed at averting a pandemic were imposed.

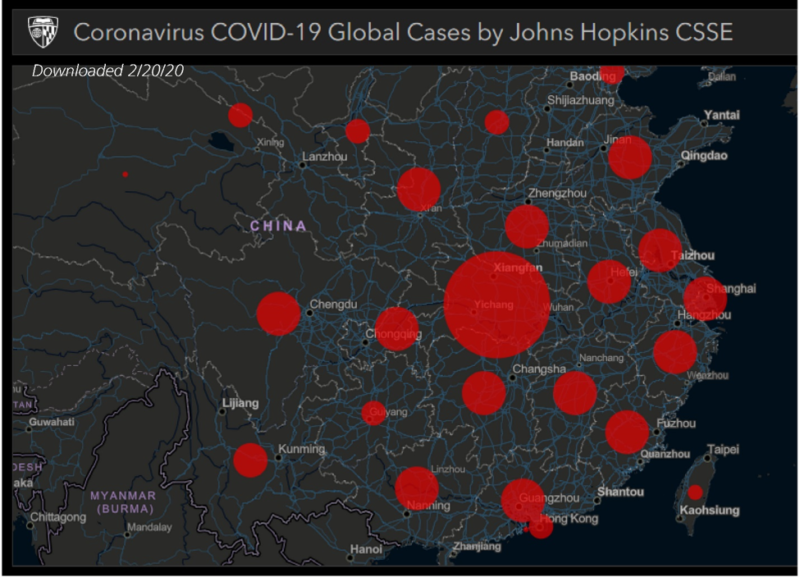

As the following map downloaded from Johns Hopkins on February 20 indicates, Hubei is ground zero for the Wuhan coronavirus, designated 2019-nCoV by the World Health Organization,

[John Hopkins Center for Systems Science and Engineering (CSSE) is tracking the spread of 2019-nCoV in real-time. Cases and locations can be viewed here.]

While well down the export rankings at No. 17, Hubei is among China’s top logistics hubs and production centers for steel, cars, trucks, and heavy machinery as well as agricultural and other chemicals, foodstuffs, textiles, and electronics.

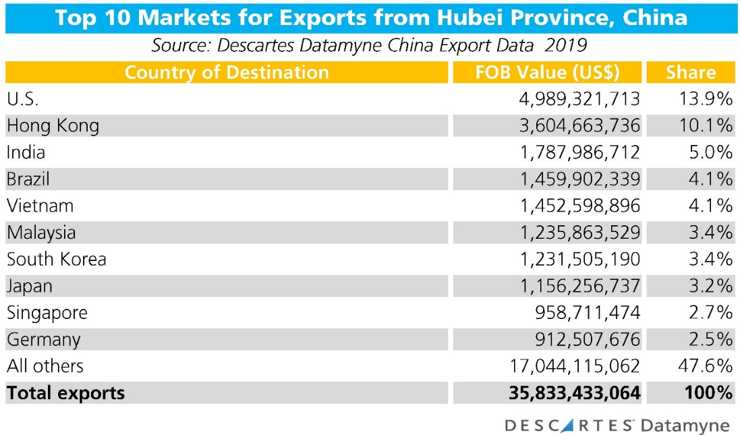

Much of this production is for domestic consumption. The top market for Hubei goods earmarked for export is the U.S., destination for 13.9% by value of trade last year. Here are Hubei’s top 10 markets, based on our China trade data:

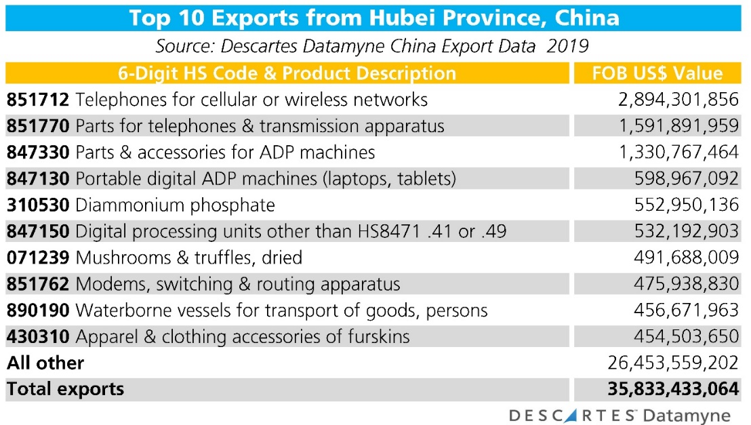

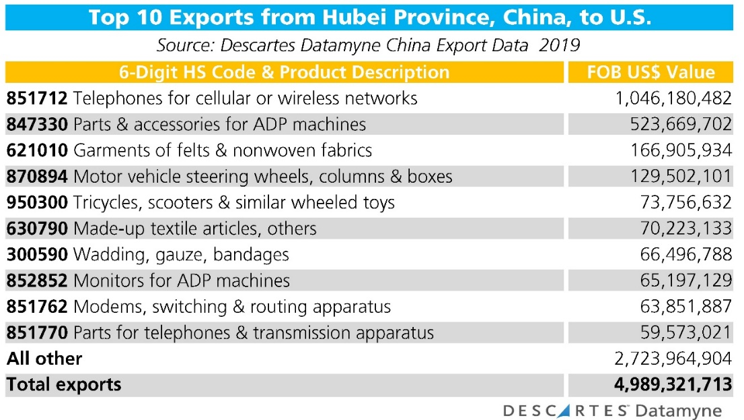

Our trade data indicates that Hubei’s production for export is concentrated in electronics, a newer, growth industry for the early-to-industrialize province. Here are Hubei’s top 10 exports by value in 2019:

Hubei steps up in rank among Chinese production centers as a source for cell phones (at No. 7, accounting for 2.3% share in 2019) and parts for phones and transmission equipment (No. 6, with a 3.3% share). These products are an important part of the mix that goes to the U.S., as our data indicates:

Note, too, our next table showing parts for telephones and transmission apparatus representing the biggest slice of Hubei’s exports bound for Vietnam – an indication that the Chinese province is an important link in supply chains for phone manufacturers in Vietnam. This bodes ill for U.S. importers relying on Vietnam as an alternate source for cell phones. The up-and-coming producer of phones accounted for nearly 20% of U.S. imports denoted HS851712 last year (China accounted for 72%). But with its input supply chains running through China, the Vietnamese industry is likely to see significant disruptions in production, even if the coronavirus remains contained. (So far, only a handful of cases of the disease have been reported in Da Nang.)

Here are the other top destinations for Hubei’s exports of parts for telephone and transmission apparatus:

Coronavirus Stress Test: Rerouting Supply Chains

Our multinational trade data enables us to build a more detailed map of the outbound trade flows from Chinese province, to port, to destination.

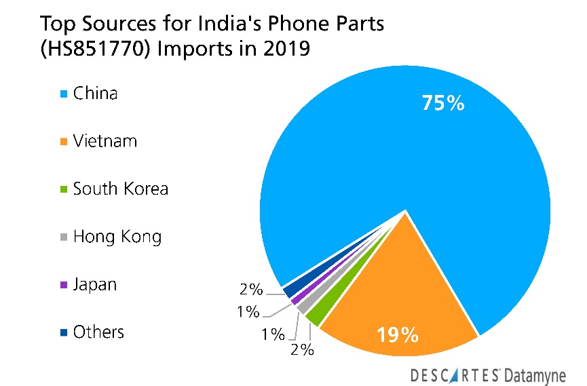

We can also switch from the sell-side perspective to the buy-side perspective. While the China data indicates that India is a top market for phone parts, our India trade data provides a measure of how reliant on, and vulnerable to disruption from China the Indian mobile phone industry is.

Drilling down in our India trade data reveals the names of the companies shipping product to and taking delivery of phone parts. Shippers and importers are also identified in our Vietnam data.

Similarly, a deep dive into Descartes Datamyne U.S. bill-of-lading import data, with its transactional detail, yields added insight into supply chain exposure to disruption from measures aimed at slowing the spread of coronavirus.

The top ranks of consignees for U.S. imports categorized as HS851770 are dominated by North American-based assemblers of smartphones on the IOS and Android platforms, generally (but not exclusively) relying on related parties as suppliers.

Our Trade Profiles product offers a short-cut to searching directly for companies buying and selling in the global marketplace. Our search for suppliers of phone parts based in Mexico netted 49 shippers. The Trade Profiles dashboard includes a complete list of relevant companies, locations and contact information. Each listing is linked to a profile of the company’s current trade activities, with a further option of drilling down to the underlying transaction records.

We’ve been focusing on China export data with an eye towards rerouting supply chains through other countries and identifying new sources of supply. But, of course, sellers can use the trade data to identify country markets facing shortfalls in China-sourced supplies (such as Russia, which has closed its border with China) and potential customers feeling the pinch as just-in-time deliveries are indefinitely delayed.

Beyond the supply and demand of trade goods, the availability of transport is being constricted. With fewer containers laden with Chinese imports arriving at U.S. ports, few empty containers are available for U.S. exporters to ship their goods out. Ships stuck in quarantined ports will inevitably mean backlogs in offloading (recall the congestion at U.S. ports along the Gulf in the wake of Hurricane Harvey). Our maritime data – and especially our U.S. bill-of-lading import data released 24 hours after ship arrival – is being used to track the impact of 2019-nCoV on logistics and to plot workarounds.

The U.S.-China trade war has been an impetus for supply chains to beef up resilience by diversifying sources and planning for contingencies. While there is evidence in the trade data of a shift to new production centers in Vietnam and other Southeast Asian countries, there clearly is still a concentration of suppliers in China, notably in electronics, but also in pharmaceuticals, automobiles and, to a lesser extent than in the past but still significant, apparel. This latest “bug-driven” stress test of global supply chains should be an added goad to find alternative sources whether at home, near-shore or abroad.

Related:

Blog:

- U.S.-China Phase One Agreement Focuses on Relationship Reset [Editor’s Note: The coronavirus will almost certainly challenge China to meet its new commitments for U.S. purchasing as part of the U.S.-China trade agreement.]

- Trade War Reshapes U.S. Import Peak Shipping

- U.S. Auto Exports and the Impact of Shifting Trade Policy

Resources:

- Our multinational trade data assets can be used to trace global supply chains and our bill-of-lading trade data – with cross-references to company profiles and customs information – can help businesses identify and qualify new sources. Ask us for a free, no-obligation demonstration of our data on a product or trade commodity of your choosing – and keep the custom research we create with our compliments.